A Practical Toolkit to Reduce Lithography Process Variability

As integrated circuit (IC) designs increase in complexity they become even more sensitive to contaminants that can negatively impact yield or device performance. One way to eliminate potential contaminants from IC manufacturing is to leverage filtration and purification technology in many parts of the process.

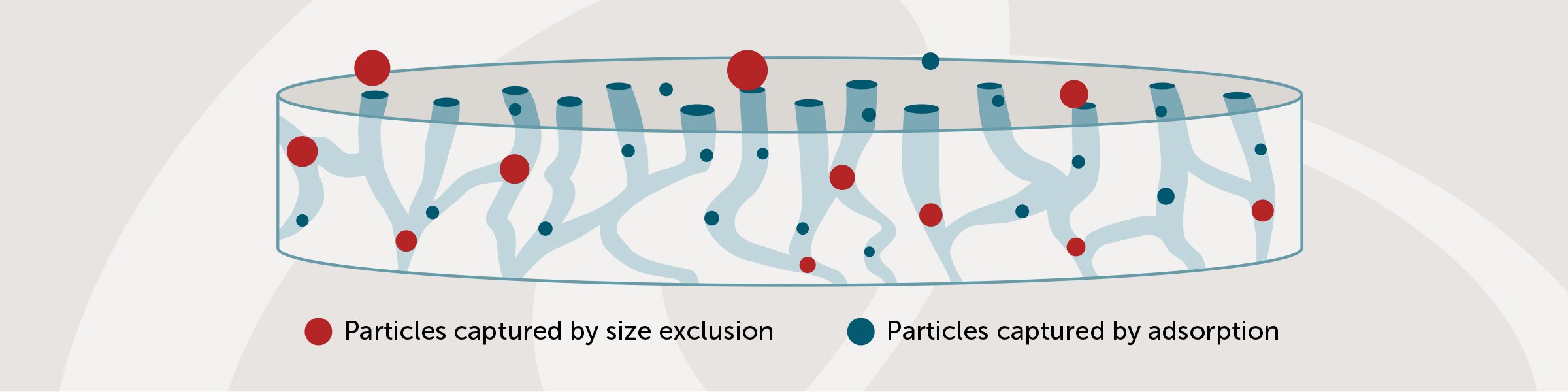

Liquid filtration primarily uses polymer membrane technologies. Membranes are selective barriers that permit certain constituents in a fluid stream to pass through while retaining or rejecting others. A common misconception about membranes is that they are simply sieves that have one consistent pore in one barrier layer that retains all contaminants larger than the pore size.

In fact, often the results of these different methods contradict one another, simply because the retention mechanisms that determine filtration effectiveness differ for each of the methods. While there is value in performing these measurements to better understand filtration performance, ultimately the retention rating is a guide, not a direct measurement.

This paper explains that lithographers should consider filtration early in their process design to address variability that negatively impacts yield and reliability, and it explains how emerging technologies in membrane materials, membrane morphologies, and surface modification are expanding our understanding of retention mechanisms in modern photochemicals.