We are delighted to sponsor Silicon Saxony Day, one of Europe's premier international high-tech and networking events. This dynamic platform facilitates business and research networking and presentations.

This year, the focus is on "technology islands," each dedicated to selected industry-relevant topics. These islands provide a unique space where participants, experts, and exhibitors can engage in meaningful exchanges, share first-hand best practices, and explore current trends and demonstrators.

We are delighted to sponsor Silicon Saxony Day, one of Europe's premier international high-tech and networking events. This dynamic platform facilitates business and research networking and presentations.

This year, the focus is on "technology islands," each dedicated to selected industry-relevant topics. These islands provide a unique space where participants, experts, and exhibitors can engage in meaningful exchanges, share first-hand best practices, and explore current trends and demonstrators.

/content/entegris-live/en/home/about-us/events/silicon-saxony-day-2025Join Us | Microelectronics Island | Booth A19

As a leading supplier of advanced materials and process solutions for the semiconductor industry, we invite you to visit us at the Microelectronics Island. This is an excellent opportunity to meet our local experts and discuss your specific challenges. Be sure not to miss our presentation on sustainability, a core pillar of our commitment to Corporate Social Responsibility.

Sustainability is deeply embedded in everything we do. From enabling the desalination industry to regenerating gas purifiers for semiconductor manufacturing at our German facility, we are dedicated to creating solutions that drive innovation while supporting a more sustainable future for our planet.

featured Presentation

June 17 | 12:05-12:15 p.m.

INNOVATIVE APPROACHES FOR ENHANCING SUSTAINABILITY IN SEMICONDUCTOR MANUFACTURING

Session: Sustainability and Green Transition

Speaker:

Antoine Amade, President EMEA

Access to potable water is a major global challenge. In many parts of the world, desalination is the only viable solution. However, this process is highly energy-intensive and requires significant chemical usage, creating serious environmental concerns.

But what if a simple improvement could make a difference?

Filtration, a critical component of desalination, has the potential to drive major change. By optimizing filtration systems, we can significantly reduce energy consumption and minimize chemical use, making desalination more sustainable and efficient.

And the impact goes beyond water. Filtration is also essential in the semiconductor industry, where even the smallest impurity can lead to costly defects. Here, too, better filtration management reduces chemical usage and, most importantly, enhances equipment uptime—leading to fewer interruptions and a more efficient production process.

This presentation will take you through these challenges and explore concrete solutions. It will highlight key environmental initiatives, including sustainability programs focused on CMP materials recycling, gas purifier regeneration, and packaging.

Event Related Content

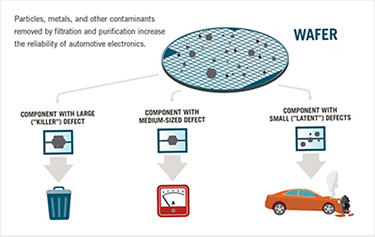

As automotive electronics become more complex and prevalent, the cost of failure in these devices rises. Hidden defects caused by small particles, gels, metal ions, and organic contaminants can lead to failures throughout the vehicle’s life, escalating costs and increasing risks. How can you prevent hidden defects?

To achieve optimal wafer yield and reliability, the microelectronics industry needs to address increased materials consumption requirements and materials purity challenges from chemical manufacture to point of use.

Achieving your zero-defect goals requires contaminant-free process gases. Preventing these defects requires a holistic approach from the gas generation source through the delivery, storage, and dispense steps in the semiconductor fab.

Achieving the performance goals of a new generation of automotive electronics requires a precise precursor and plasma gas combination.

The selection can be done with ease using the Entegris toolbox.

Wafers are continuously transported and stored through the front and back end of semiconductor manufacturing lines. Entegris solutions prevent corrosion that may lead to reliability failures and wafer breakage during these critical steps, helping to reduce wafer and component defects.