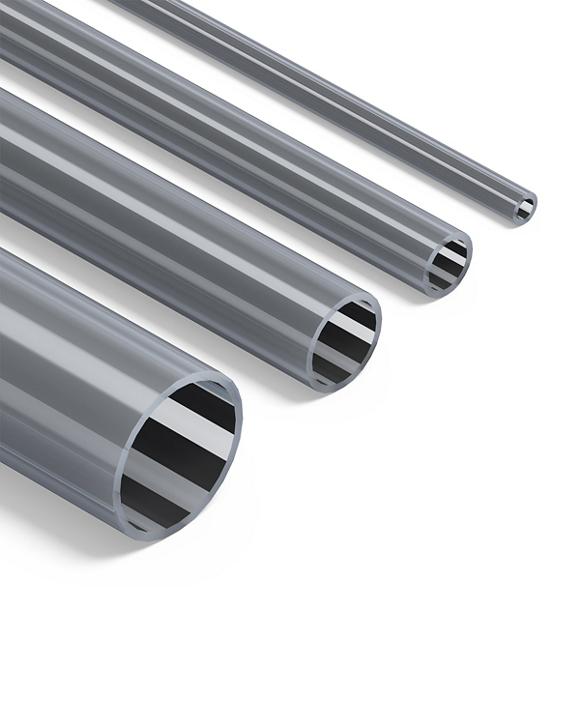

FluoroLine® Plus ESD Tubing

To discuss your specific needs, contact your local Entegris representative.

Don't have an Entegris representative?

Contact UsThank you for requesting a quote. Someone from Entegris will contact you shortly.

Your quote number is {0}.

Notes:

- Quantities between roll and reel length maximums will be packaged on a reel

- Tight and consistent tolerances, along with lot-to-lot consistency are maintained using continuous online measurements of the FluoroLine tubing OD and wall thickness.

- Flammable chemistries such as solvents and other nonconductive semiconductor chemistries

- High-purity, corrosive chemical handling

- Excellent performance with low surface tension chemistries

- Solar, LED, flat panel display

- Semiconductor applications

- Photolithography

- Bulk chemical delivery

- CMP

- Wet etch and clean

- High-temperature cleaning processes

Specifications

| Size | Outside Diameter (A) | Wall Thickness (B) | Outside Diameter Tolerance | Wall Thickness Tolerance | Minimum Bend Radius |

| 1/4" | 0.250" (6.35 mm) | 0.047" (1.194 mm) | ±0.004" (±0.102 mm) | ±0.004" (±0.10 mm) | 1.5" (38 mm) |

| 3/8" | 0.375" (9.52 mm) | 0.062" (1.575 mm) | ±0.004" (±0.102 mm) | ±0.005" (±0.127 mm) | 2.0" (51 mm) |

| 1/2" | 0.500" (12.70 mm) | 0.062" (1.575 mm) | ±0.005" (±0.127 mm) | ±0.005" (±0.127 mm) | 2.3" (58 mm) |

| 3/4" | 0.750" (19.05 mm) | 0.062" (1.575 mm) | ±0.005" (±0.127 mm) | ±0.005" (±0.127 mm) | 9.0" (229 mm) |

| 1" | 1.000" (25.40 mm) | 0.062" (1.575 mm) | ±0.005" (±0.127 mm) | ±0.005" (±0.127 mm) | 11.0" (279 mm) |

| Size | Tube Size OD | ID | Minimum Bend Radius | MOQ (ft) | Maximum Roll Length (ft) | Maximum Reel Length (ft) |

| 1/4" | 0.250 (6.35 mm) | 0.156 (3.96 mm) | 1.5 (38 mm) | 500 | 500 | 2500 |

| 3/8" | 0.375 (9.52 mm) | 0.251 (6.38 mm) | 2.0 (51 mm) | 500 | 500 | 5000 |

| 1/2" | 0.500 (12.70 mm) | 0.376 (9.55 mm) | 2.3 (58 mm) | 500 | 500 | 4000 |

| 3/4" | 0.750 (19.05 mm) | 0.626 (15.90 mm) | 9.0 (229 mm) | 250 | 250 | 1500 |

| 1" | 1.000 (25.40 mm) | 0.876 (22.25 mm) | 11.0 (279 mm) | 250 | 250 | 750 |

Pressure/Temperature Ratings

FluoroLine PFA tubing pressure ratings were established using ASTM D2837. This test exposes the tubing to long-term, constant pressures at various temperature settings. Our test took 22 months to complete. From the analysis, a hydrostatic design basis (HDB) value is multiplied by a safety design factor to obtain a hydrostatic design stress. The HDB value is used to determine the tubing operating parameters. FluoroLine PFA tubing completed this extensive testing.

All FluoroLine tubing products are fully characterized and all performance ratings are derived from quantifiable data. Our design and process expertise allow you to confidently design your fluid systems reliably and safely.

Pressure Loss vs. Flow

(Reference the 2nd, 3rd, and 4th charts)

This data is for water (fluid with s.g. = 1.0).

For pressure loss vs. flow capability outside of these calculations, please contact Entegris.

| Materials of construction: | Combination of conductive PFA and 100% virgin PFA 451 HP resin | |

| Surface resistivity: | 1 x 105-6 Ohm/sq | |

| Sizes available: | 1/4" to 1" | |

| Approvals: | ||

Laser Marking Codes

ENTEGRIS ESDT 4 0123456789

| OD Size | Work Order Number |

| 4 = 1/4" (6.4 mm) | Work order number traceable to a specific material lot number, date manufactured, and production inspection record |

| 5 = 5/16" (7.9 mm) | |

| 6 = 3/8" (9.5 mm) | |

| 8 = 1/2" (12.7 mm) | |

| 12 = 3/4" (19.1 mm) | |

| 16 = 1" (25.4 mm) |

Maximum Pressure Rating Chart

FluoroLine Ultrapure PFA Tubing

Maximum pressure capabilities of various sizes are listed below. These ratings are provided as a guide in system design. The component with the lowest maximum pressure rating determines your system maximum pressure rating.

| Size (X) | Temperature °F (°C) | FluoroLine Plus ESD PFA Tubing psig (kPa) |

| 1/4" | 75 (24) | 273 (1882) |

| 200 (93) | 136 (938) | |

| 250 (121) | 85 (586) | |

| 300 (150) | 61 (421) | |

| 350 (175) | 36 (248) | |

| 400 (200) | N/R | |

| 3/8" | 75 (24) | 234 (1613) |

| 200 (93) | 116 (800) | |

| 250 (121) | 73 (503) | |

| 300 (150) | 52 (359) | |

| 350 (175) | 31 (214) | |

| 400 (200) | N/R | |

| 1/2" (8) | 75 (24) | 168 (1158) |

| 200 (93) | 83 (572) | |

| 250 (121) | 52 (359) | |

| 300 (150) | 37 (255) | |

| 350 (175) | 22 (152) | |

| 400 (200) | N/R | |

| 3/4" | 75 (24) | 107 (738) |

| 200 (93) | 53 (365) | |

| 250 (121) | 33 (228) | |

| 300 (150) | 24 (165) | |

| 350 (175) | 14 (95.5) | |

| 400 (200) | N/R | |

| 1" | 75 (24) | 77 (531) |

| 200 (93) | 38 (262) | |

| 250 (121) | 24 (165) | |

| 300 (150) | 17 (117) | |

| 350 (175) | 10 (68.9) | |

| 400 (200) | N/R | |

| N/R = Not rated |

Successfully Opted for software Updates

Electrostatic Dissipative ESD Tubing and Fittings

| Part Number | Tube Size |

|---|---|

| ESDT1000-062 | 1" |

| ESDT250-047 | 1/4" |

| ESDT375-062 | 3/8" |

| ESDT500-062 | 1/2" |

| ESDT750-062 | 3/4" |

Notes:

- Quantities between roll and reel length maximums will be packaged on a reel

- Tight and consistent tolerances, along with lot-to-lot consistency are maintained using continuous online measurements of the FluoroLine tubing OD and wall thickness.